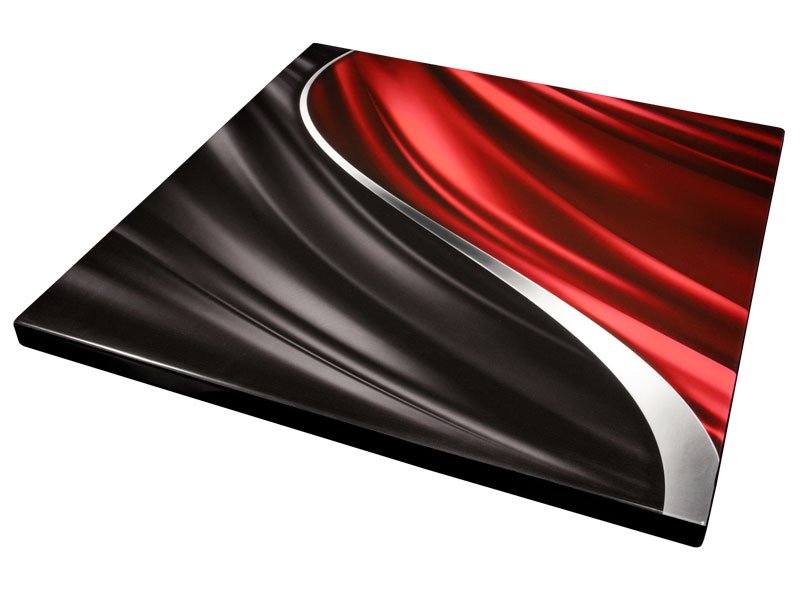

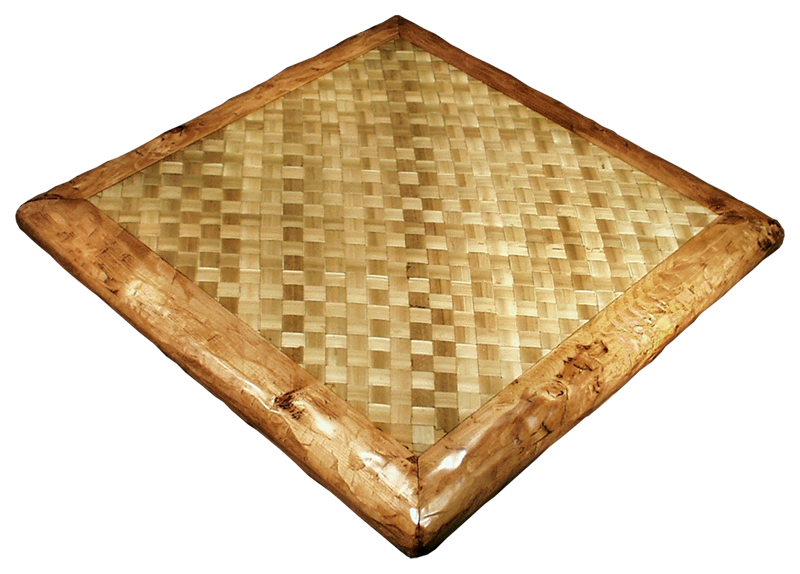

Table Topics is your premier source for custom commercial dining tables and home to the most durable finish in the hospitality industry, Acralyte. Table Topics can help design & engineer your perfect restaurant table tops and we produce your vision using the highest quality materials with the most advanced finish in the industry, making your tables as durable as they are stunning.

Acralyte

Acralyte is an acrylic resin that is chemically engineered to achieve greater scratch, mar, chemical & heat resistance than traditional furniture finishes (such as epoxy resin, polyester resin, urethane and conversion varnishes).

Acralyte’s proprietary chemical formulation allows for it to achieve these elevated levels of protection on a consistent basis by using a UV curing process. By curing the finish with UV lights (instead of air, heat or chemical hardeners) the finish is fully cured after it passes through a UV light oven. Traditional finishes can be cured enough to ship but may take weeks or months before they are fully cured. This can result in an initial “break in” period during which the finish is susceptible to a greater risk of damage than after a full cure is achieved. Even when fully cured, though, traditional furniture finishes still fail in comparison to Acralyte. Scratching, marring, chemicals and heat can cause all furniture finishes to fail before the life of the furniture has run out and this is especially true with restaurant table tops. Commercial table tops are used multiple times on a daily basis. If the finish can’t withstand that environment it is only a matter of time before the tables will have to be replaced. Acralyte offers an unmatched level of scratch & mar resistance in the furniture industry. Nevertheless, dinnerware with abrasive undersides and other coarse items used in service can still cause the finish to scratch or become hazy.

Acralyte X

Acralyte X is the next chapter of the Acralyte story. Through extensive research and development, we have created a fine furniture finish that improves upon everything that we have accomplished thus far and adds a new advantage to with our inclusion of an anti-microbial in its chemical foundation. It's chemical and alcohol resistant, featured exceptional scratch wear and resistance, is heat ring resistant up to 250 degrees, and has the anti-microbial agent built into the finish.